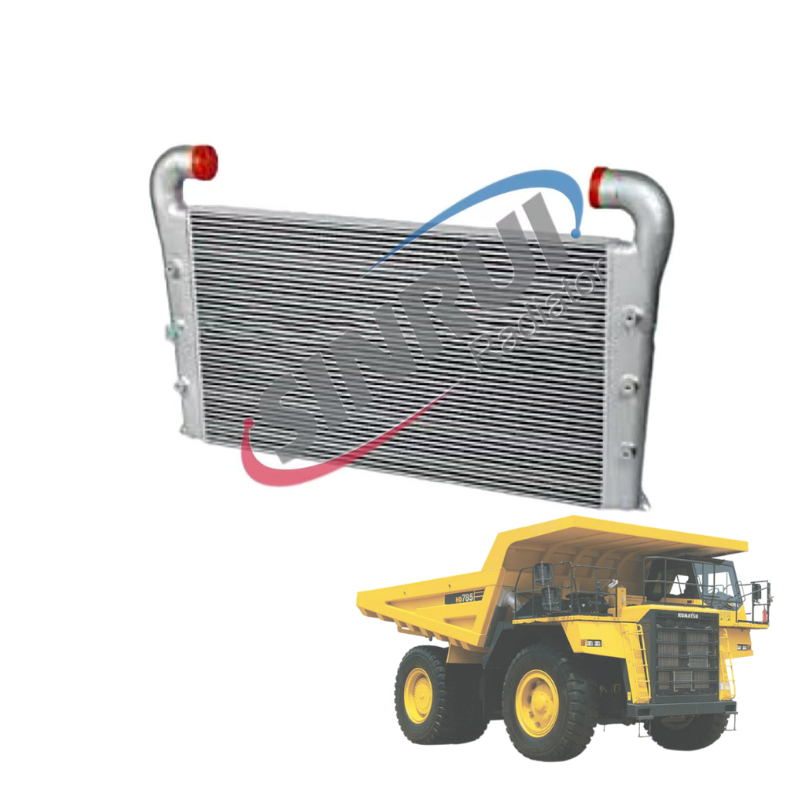

Dalilai Masu Mahimmanci na Kafaɓe Hadi a Cikin Tsarin Radiator na Maƙiyya

Ammarwa da Kafaɓe Hadi a Dukkin Fasshar Ruwa

Sadarwar Kofuna za a iya kula da kama'a mai yawa ta hanyar amfani da alama da kula da yadda za a sarrafa ruwa. Lokacin da ke bayan bayan, kama'a zai motsa daga abubuwan ƙasa zuwa sauya mai kyau wanda ke tsawon shadiken masallaci. Wadannan nukarin bayan bayan na iya samun sanya sosai, kada kusan 200 daraja Farenhaya lokacin da ke aiki a matsayin ƙarami. Tsari na tufafi na flat tube a cikin wadannan radiators suna bada maɓalli mai girma ga alamun kama'a, wanda yake nufin su karɓe kama'a ne akan kewaye 40% fiye da tubular mai tsutsuwa. Bayan sauya ya ci gaba da ninka kamar kama'a duk wadannan ta hanyar kanalolin mai tsada coppa da aluminium. Coppa yana da nasarar mai kyau na thermal, sai dai kyakkyawa don kara kama'a kusa da engine block. Aluminium yana aiki kyakkyawa kuma, saboda ita ce babban da kasancewar iyaka yayin da ta yi aiki mai kyau na furta kama'a a cikin radiator n itself. Kama'a ta kama'a ke taimaka wajen baya waɗannan yanayin kama'a mai tsada wanda zai iya kare abubuwan mahimmanci na mesin kuma ta kama'a dukkan abuwa a cikin yankin normal

Za a iya yawa daga ruwa zuwa sama ko daga ruwa zuwa ruwa a Radiator na yankin dauni Makamashi

Za a basu zabin hanyar fitar da hankumi ne akan tsarin aiki da kimaɗin samun gudu:

- Sistemin ruwa zuwa sama sun sauya ayyukan sarki, yin amfani da radiyatorin da aka nuna su da gudun gudu wanda ya shiga samuni don fitar da hankali har abubuwan sama. Sun iya samun kama zuwa 70% kwayoyin tsaron hankali a cikin angojin rigakwato amma sun kasance mai karancewa a cikin halayen alashan—kayan alashan na iya raguwa kwayoyin tsaro ta hanyar kama zuwa 25%.

- Sistemin ruwa zuwa ruwa , wanda aka guddata a juyin ƙasa, yana bada hankali zuwa wasu sadarwar ruwa ta hanyar maye tsoro mai zurfi. Wannan hanyar yadda ya yi ke kawo kama da 80—85% kwayar aiki a cikin waje mai daraja, wanda babu gudu, amma yana buƙatar kayan ajiya da ba za a iya kaiwa masa kamar stainless steel don tafi da kimiyyar ruwan gojin.

| Abubuwan da ake kimantsi | Ruwa zuwa sama | Ruwa zuwa ruwa |

|---|---|---|

| Tsumina Ingantattun | Ƙofar ta sama | Ayyukan kwallike |

| Shafin Tattara | 60—70% | 80—85% |

| Takaitaccen Wurin Gudanawa | Karin dusta mai dakin gurasa | Juriya na Lalata |

Zaɓi ya dace da kwana ɗin ruwa, ingancin gudumarwa, da shafukan wurin—tare da sauyin halitta masu yawa a wadankan wuraren da ke sama mai ƙarfi inda duk ruwan sama da kwana ɗin guddafa sun kama.

Abubuwan Kayan Aikin Makulluka Mai Lahira na Makulluka Mai Guddafa Ruwa

Tsari mai zurfi na Tube mai flat da tsari na tube-fin don alamomin mai hankali

Haɓakar flat-tube a cikin ririji na mayan ganye yaƙiƙiyar biyu: suna tafi da kewayon kewayon ruwa sai dai kuma ke tafiyya da shahara mai zurfi wanda masu ganye ke fuskantar sakamako. Dua zuwa duka wadannan rigogun daga abubuwan kayan aiki mai zurfi, gwajiyan gudu sun fito dari kayan aiki, da kuma rigogun majabbo a cikin mayan ganye mai zurfi da koro mai zurfi. Yawan fin na tube (kamar yadda aka fi saba'bi 12 zuwa 16 per inch) yana koyo hankali kan tsarin bauta idanu ko slurry ta zama tsakanin su. Wasu kwamfuta masu sha'awar fluid dynamics suna nuna cewa yanayin fin mai amfani da turbulators talaka yana kare karin resistance na thermal kamar karkashin ikwata dibu darasi ga fin mai nema. Wannan ya kunshi saboda matsalolin corrosion kusa kawai suna chetchewa kuduren dollars seven hundred forty thousand kowace shekara daga kuyun gine-ginen mayan ganye, kamar yadda aka faɗi shine akan kwamfuta na International Council on Mining and Metals a 2023.

Abubuwan da ba za a yi wa su corrosion da Coatings da ba za a yi wa su fouling

Abubuwan da ke tsaye kamar alatiku, brass mixtures, da coatings da suka shiga graphite suna tafi daidai da abubuwa kamar acid na sulfuric, damage na saltwater, da kuma mine slurries masu gudu wanda ya kulle matakan kwakwalwa. Prosess din elektrorophoretic coating ko E-coating yana haifarawa wannan layi mai zurfi a nanoscale level wanda ke tsaya scale ta dawo a cikin coolant systems. Wasu tests na musamman suna nuna cewa coated systems suna da batun fouling mai zurfi ne 90% kaananan bayan an fitar da su 5,000 hours dibu da wasu sashe uncoated. Wannan yana muhimci saboda bisa ga report mai mahimmanci a kan durability na mining equipment wanda aka release sanu, takambu biyu na uku na duk breakdowns na heat exchanger suna da wahala ta hanyar corrosion issues. Hakanan akwai waɗannan double layer treatments wanda suka tsaya ruwa, kuma suka tsaya slurry ta dawo a cikin yanayin masu mahimmanci, wanda ke saha matakan kwakwalwa a cikin yanayin gaskiya.

Applications na Critical Cooling da suka iya Mining Radiators

Gudummawar Rahotun Kwayar Tsararen da Rahotun Makinai

Rarararar da ke tsaron gudummawar kwayar tsararen yana kiyaye tsawon gudummawar kwayar tsararen a tsawon 45 zuwa 65 daraja Silisiya lokacin da abubuwa ke bugun bugun sosai sosai. Wannan yana kiyaye kwayar tsararen daga kiyama mai tsawon, wanda zai iya haifar da matsalolin da suka fi kama, kamar yadda kwayar tsararen ke kama, kwayar tsararen ke kama, da kwayar tsararen ke kama. A wakilan hakanan, yaukunan wannan nukarin yana kiyaye 30 zuwa 40% na gudummawar da aka yi a cikin nukarin kwayar tsararen. Wannan yana taimakawa wajen kiyaye kwayar tsararen daga kiyama da kiyama, kamar yadda kwayar tsararen ke kama, da kwayar tsararen ke kama. Gudummawar tsawon yana da mahimmanci a kama’ayar abubuwa. Datos na sarrafa ta bayanai cewa nukarin da aka kiyaye suna iya kiyaye kama’ayar abubuwa ta 2 zuwa 3 shekara tambayar kamar yadda kwayar tsararen ke kama, da kwayar tsararen ke kama.

Izini da Kiyaye Gudummawar da Kiyaye Gudummawar

Yanayin radiator na yau da kullun yana amfani da kayayyakin da ke karkashin haɓakawa tare da cututtuka masu inganci wanda ke iya fuskantar hanyoyin cajjin sabin ko brazing ba tare da haɓaka sarari. Lokacin da kayayyaki suka canzawa a cikin tsawon core na radiator, yana taimakawa wajen kula da waɗannan alamuwa na gafara lokacin da kayayyaki suka zama satsa bayan kammalawa ko yawan abubuwa suka taguwa. Bayani daga maintenance mai aminci yana nuna cewa wannan inganci yana kara katkatawa a cikin wayar 17% a cikin angoji masu runde 24/7. Kuma yayin da aka haɗa shi da finai masu shape mai kyau, wadannan radiators suna tsaba tashe karfi sanza bayan bayan dust ya yi karfi, sannan suna zama abubuwa masu amintam ce a cikin halayyen masu dainarwa inda baya ba zai iya buƙatar.

Sashen Tambayoyi

Wanne ne sunayen ilimin tashe karfi a cikin yanayin radiator na goyon?

Haɓakar hankali a ƙusurwar maɓaɓɓiyar yanki ya ƙara ta hanyar ƙwayar yanki da kwayar ruwa. Ƙusurwar yanki suna amfani da tsari mai nisa ko flat tube don zabi yanki don kwayar hankali, yayin da ruwan kamar coolant suna ƙarɓar hankali ta hanyar channel na copper da aluminum.

Yaushe liquid-to-air da liquid-to-liquid system su daban a ƙusurwar maɓaɓɓiyar yanki?

An samun system na liquid-to-air a gabashin yanki, an amfani da forced airflow don sanyar hankali, yayin da an yi system na liquid-to-liquid a ƙasa don sa ƙarin aikatawa a wadanda ba da shafin hankali, an amfani da coolant na biyu ta hanyar plate exchanger mai nisa.

Mene ne ƙusurwar yanki mai tsarin majuba ke chiyasa don ayyukan yanki?

Ƙusurwar yanki na yanki suna da tsarin majuba kamar flat-tube da tube-fin don kama da harshen halayyen yanki, daga gudunmawa ta hanyar mesin zuwa kalmala, don kiyaye kwayar hankali da tsaro aikin ƙusurwar yanki.

Shin abubuwa da aka amfani da su don kula da kuyarwa a cikin radiators na mining?

Abubuwa kamar yadda keke da tsangarorin alƙawali, tsangarorin da ke nambobi, da tsangarorin electrophoretic (E-coating) ana amfani da su don kula da kuyarwa, kula da dabi3a mai tsutsuwa, ruwan yaki, da slurry, kuma nema karfi mai dakin.

Yaushe ne tsarin radiator na yauyin yanzu ya ƙara inganci a cikin ayyukan mining?

Tsarin radiator na yauyin yanzu yana amfani da abubuwa da tsarin da ke iya kula da dutsen thermal da girman girman temperature domin kula da karfi mai dakin abu, kuma nema karanin cutarwa da kuma ƙara girman abubuwa a cikin ayyukan mining da ke dauke da tsaki.

Teburin Abubuwan Ciki

- Dalilai Masu Mahimmanci na Kafaɓe Hadi a Cikin Tsarin Radiator na Maƙiyya

- Abubuwan Kayan Aikin Makulluka Mai Lahira na Makulluka Mai Guddafa Ruwa

- Applications na Critical Cooling da suka iya Mining Radiators

-

Sashen Tambayoyi

- Wanne ne sunayen ilimin tashe karfi a cikin yanayin radiator na goyon?

- Yaushe liquid-to-air da liquid-to-liquid system su daban a ƙusurwar maɓaɓɓiyar yanki?

- Mene ne ƙusurwar yanki mai tsarin majuba ke chiyasa don ayyukan yanki?

- Shin abubuwa da aka amfani da su don kula da kuyarwa a cikin radiators na mining?

- Yaushe ne tsarin radiator na yauyin yanzu ya ƙara inganci a cikin ayyukan mining?