Core Heat Transfer Principles in Mining Radiator Systems

Thermal Absorption and Conduction Across Fluid Loops

Mining radiators handle massive heat buildup by using conduction and managing how fluids move around. When engines run hard, heat moves from metal parts directly into coolant that flows through sealed circuits. These systems can get pretty hot too, sometimes reaching over 200 degrees Fahrenheit when working at full capacity. The flat tube design in these radiators actually gives them a bigger surface area for conducting heat, which means they absorb heat about 40 percent faster compared to traditional round tubes. The coolant then carries away all that heat through special copper and aluminum alloy channels. Copper has really good thermal properties, making it great for grabbing heat right next to the engine block. Aluminum works well too since it's lighter and cheaper while still doing a decent job of spreading out the heat across the radiator itself. Keeping coolant moving constantly helps avoid those dangerous hot spots that could damage important engine parts and keeps everything running safely within normal limits.

Liquid-to-Air vs. Liquid-to-Liquid Rejection in Mining Radiator Contexts

Heat rejection method selection depends on operational environment and airflow constraints:

- Liquid-to-air systems dominate surface operations, using finned radiators and forced airflow to dissipate heat into ambient air. They achieve up to 70% thermal efficiency in open-pit mines but lose effectiveness in dusty conditions—particulate accumulation can reduce heat transfer by as much as 25%.

- Liquid-to-liquid systems, deployed primarily underground, transfer heat to secondary coolants via compact plate exchangers. This approach maintains 80—85% efficiency in confined, low-ventilation settings, though it demands corrosion-resistant materials like stainless steel to withstand aggressive mine water chemistry.

| Comparison Factor | Liquid-to-Air | Liquid-to-Liquid |

|---|---|---|

| Operating Environment | Surface mines | Underground operations |

| Efficiency Range | 60—70% | 80—85% |

| Maintenance Challenge | Particulate fouling | Corrosion resistance |

Selection hinges on airflow availability, contaminant exposure, and spatial constraints—with hybrid configurations gaining traction at high-altitude sites where both ambient density and cooling capacity are reduced.

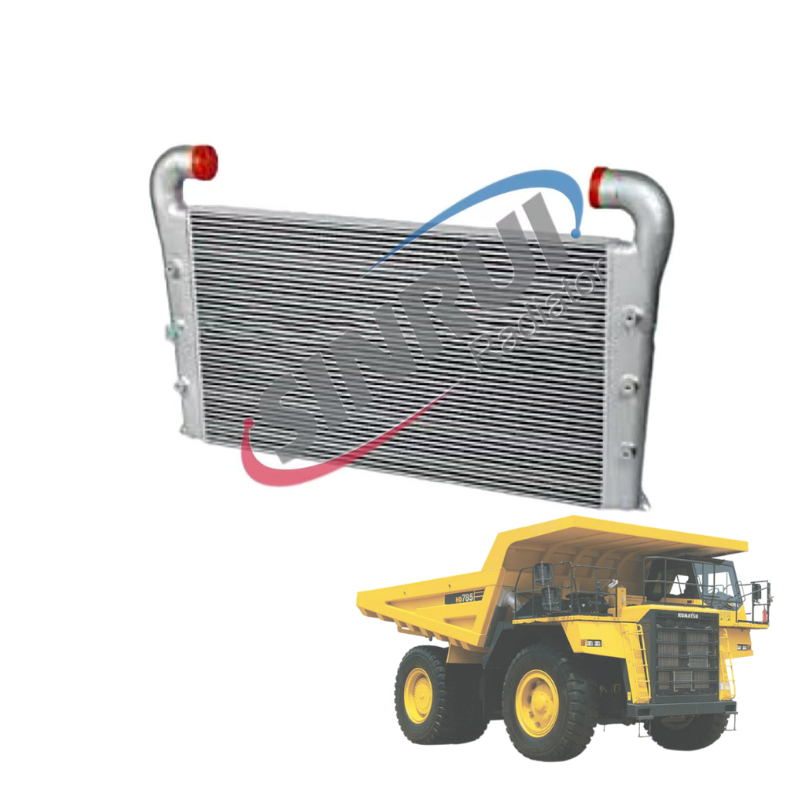

Mining-Rated Design Features of Radiator Heat Exchangers

Robust Flat-Tube and Tube-Fin Configurations for Harsh Environments

Flat-tube geometry in mining radiators serves two main purposes: they handle heat transfer efficiently while standing up to the rough conditions miners face daily. Think about all those vibrations from heavy machinery, rocks bouncing off equipment, and sudden impacts in both surface mines and deep underground tunnels. The high density of tube fins (around 12 to 16 per inch) keeps air flowing properly even after dust buildup or slurry gets stuck between them. Some interesting studies in fluid dynamics show that special fin patterns with turbulators actually cut down thermal resistance by about a fifth compared to regular straight fins. This matters because corrosion problems alone are draining mining companies of around seven hundred forty thousand dollars every year, as noted in a recent report from the International Council on Mining and Metals back in 2023.

Corrosion-Resistant Materials and Fouling-Preventive Coatings

Materials like aluminum brass mixtures and coatings infused with graphite stand up pretty well against things like sulfuric acid, saltwater damage, and those rough mine slurries that wear down equipment so fast. The process called electrophoretic coating or E-coating creates this really thin layer at the nanoscale level that stops scale from building up inside coolant systems. Some independent tests found coated systems had about 90 percent less fouling problems after running for 5,000 hours compared to regular uncoated ones. This matters because according to that big report on mining equipment durability released last year, nearly two thirds of all heat exchanger breakdowns were actually caused by corrosion issues. There's also these double layer treatments that push away water and keep slurry from getting into critical areas, which makes equipment last longer overall in real world conditions.

Critical Cooling Applications Enabled by Mining Radiators

Hydraulic Oil and Engine Coolant Thermal Management Under Load

Mining radiators keep hydraulic oil temps right around the sweet spot of 45 to 65 degrees Celsius when machines run hard for long periods. This stops the oil from getting too thin which can cause all sorts of problems like pumps losing suction, valves sticking, and seals breaking down over time. At the same time these systems dump roughly 30 to 40 percent of the heat generated by combustion back into the engine coolant system. That helps protect cylinder heads from overheating and warping even when equipment runs nonstop day after day. Good temperature control actually makes a big difference in how long parts last. Industry data shows that properly maintained systems can stretch component lifespans by anywhere from two to three additional years compared to those without adequate cooling solutions.

Continuous-Operation Reliability and Thermal Stress Mitigation

Modern radiator systems now use special materials that expand properly along with carefully designed joints which can handle repeated heating and cooling cycles without causing tiny cracks in the solder or braze points. When temperatures change gradually across the entire radiator core, it helps prevent those stress points from forming when things cool down quickly after shifts end or loads suddenly drop. Data from predictive maintenance shows that these improvements actually reduce unexpected breakdowns by about 17% in mines running 24/7. And when paired with better shaped fins, these radiators keep rejecting heat effectively even as dust builds up over time, making them reliable performers in really tough operating conditions where failure isn't an option.

FAQ Section

What are the core principles of heat transfer in mining radiator systems?

Heat transfer in mining radiators is mainly accomplished through thermal absorption and conduction of fluids. Radiators use flat tube designs to enhance surface area for better conduction, while fluids like coolants carry heat away via copper and aluminum channels.

How do liquid-to-air and liquid-to-liquid systems differ in mining radiators?

Liquid-to-air systems are predominantly used on the surface, utilizing forced airflow for cooling, while liquid-to-liquid systems are preferred underground for their higher efficiency in low-ventilation areas, using secondary coolants through compact plate exchangers.

Why are robust radiator designs necessary for mining operations?

Mining radiators feature robust designs like flat-tube and tube-fin configurations to withstand the harsh conditions typical in mining, from vibrations caused by machinery to sludge accumulation, ensuring effective heat transfer and durability of radiator systems.

What materials are used to prevent corrosion in mining radiators?

Materials like aluminum brass mixtures, graphite-infused coatings, and electrophoretic (E-coating) are used for their corrosion resistance, preventing damage from sulfuric acid, saltwater, and slurry, and reducing fouling.

How do modern radiator systems improve reliability in mining operations?

Modern radiator systems employ materials and designs that handle thermal stress and fluctuating temperatures without causing material fatigue, thereby reducing unexpected breakdowns and prolonging machinery life in continuous mining operations.

Table of Contents

- Core Heat Transfer Principles in Mining Radiator Systems

- Mining-Rated Design Features of Radiator Heat Exchangers

- Critical Cooling Applications Enabled by Mining Radiators

-

FAQ Section

- What are the core principles of heat transfer in mining radiator systems?

- How do liquid-to-air and liquid-to-liquid systems differ in mining radiators?

- Why are robust radiator designs necessary for mining operations?

- What materials are used to prevent corrosion in mining radiators?

- How do modern radiator systems improve reliability in mining operations?