Why Thermal Performance Is the Core Criterion for Mining Radiator Selection

Cryptocurrency mining, where hardware faces relentless heat, demands a specialized mining radiator for sustainable operation. Mining rigs run nonstop, hammering away at graphics cards and ASIC machines until they reach critical temperatures. Consider top-tier ASIC units—each consumes 400 to 800 watts per hour, while dense racks of GPUs in confined server rooms cause heat to accumulate rapidly. Continuous operation accelerates component wear, leading to frequent hardware failures. When temperatures spike, rigs throttle performance to avoid damage, directly reducing the rate of coins mined. An optimized mining radiator is essential to dissipate this intense thermal load, maintain consistent hash rates, and protect hardware longevity. In today's competitive environment, effective cooling powered by a robust mining radiator is no longer optional—it's fundamental to maintaining profitability.

GPU and ASIC Heat Density Challenges in Continuous-Mining Environments

Mining equipment works differently from regular computer gear since these machines run almost constantly at full capacity day after day. This continuous operation generates intense heat flows that can go beyond 150 watts per square centimeter in those fancy ASIC chips. When trying to cool down air-based systems, problems arise because heat builds up between all those tightly packed mining units, leading to annoying hot spots developing here and there. If this heat doesn't get rid of quickly enough, the internal temperatures inside the chips will rise past what's considered safe for them. What happens then? The system starts slowing down performance or worse, causes actual physical damage to the silicon components themselves. Take a look at a typical setup with ten mining rigs running together. Such an operation produces anywhere from 15 to 20 kilowatts worth of heat energy. That's roughly the same amount of warmth generated by five standard home heating systems combined. So imagine needing industrial grade radiators just to keep up with all that thermal output before it becomes overwhelming for the surrounding environment.

How Thermal Resistance Directly Impacts Mining Radiator Reliability and Uptime

The thermal resistance rating measured in degrees Celsius per watt tells us how well a radiator works. Basically, the lower this number is, the better it transfers heat away from computer parts to the surrounding air. Take a radiator with a 0.5 degree per watt rating for instance. If we put a 100 watt processor inside, it would get about 50 degrees hotter than room temperature. That kind of heat buildup can really stress out components over time. On the flip side, radiators with ratings around 0.2 degrees per watt keep things much cooler. They only let the same processor rise about 20 degrees above ambient temperature, which actually makes these components last about 30 percent longer according to some studies from the Ponemon Institute back in 2023. And when it comes to data centers running nonstop, even small changes matter. For every five degree drop in operating temps, failure rates go down roughly 15 percent throughout those continuous mining operations.

Air-Cooled Mining Radiators: Cost-Effective Simplicity with Ambient-Dependent Limits

Aluminum-Fin Design Dominance and Real-World Scalability in Mid-Tier Farms

Aluminum fin heat exchangers are the go to choice for most air cooled mining radiators because they strike just the right balance between how well they conduct heat, their weight, and what they cost. These lightweight units make installation pretty straightforward in medium sized operations with around 100 to 500 GPUs running where budget limitations mean operators need something simple to install and maintain. Real world testing has found that these passive cooling systems can keep things cool enough in facilities where the surrounding temperature stays under 30 degrees Celsius. The modular nature of these systems allows for gradual expansion through additional fans as needs grow year after year, typically handling increases of about 20 to 30 percent capacity. But there is a catch worth noting: once rack density goes past about 5 kilowatts per square meter, the effectiveness of natural convection starts to drop off significantly. At that point, extra measures for managing airflow become absolutely necessary to prevent hotspots from forming.

The Critical Impact of Rising Ambient Temperatures on Convective Efficiency

As temperatures climb, convective heat transfer just keeps getting worse at an exponential rate. According to thermodynamic models we've been working with, when it gets 5 degrees hotter than 30°C, thermal resistance jumps anywhere from 15% to 18%. The reason behind this? Cooling systems basically rely on the difference in temperature between hot components and the surrounding air. Take a look at what happens when ambient temps hit 35°C during those brutal summer heat waves. A standard aluminum fin radiator will lose around 40% of its ability to dissipate heat compared to how it performs in winter conditions at 15°C. What does this mean for actual operations? Hardware starts thermal throttling pretty much automatically, which can slash hash rates by as much as 25%. For facilities located in warmer regions, this means having to install radiators that are 30% to 50% larger than normal just to keep things running smoothly. And let's face it, this kind of equipment upgrade completely eats away at any cost savings that air cooling was supposed to provide in the first place.

Liquid-Cooled Mining Radiators: Higher Efficiency, Integration Complexity, and ROI Considerations

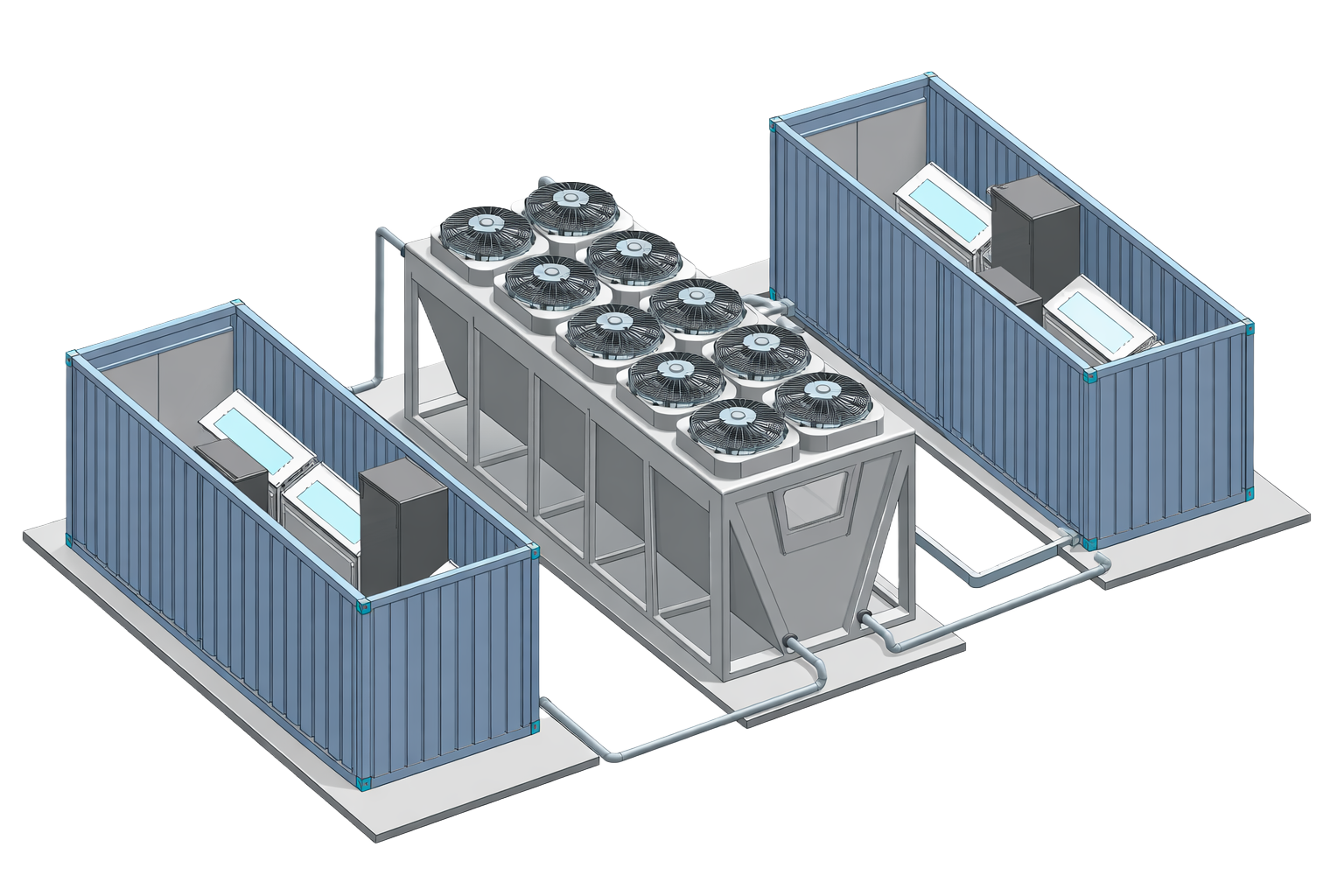

Cold-Plate and Immersion Systems in High-Density Hosted Mining Facilities

In today's high density mining operations, two main types of liquid cooling stand out: cold plate systems and immersion cooling. With cold plates, the setup involves attaching them right onto the GPUs or ASIC chips themselves. Coolant flows through tiny channels that grab all that intense heat right where it's generated. This makes sense for controlling temperatures specifically within individual racks. Then there's immersion cooling where whole mining machines get dunked into special non-conductive fluids. This approach gets rid of those pesky hot spots completely while running almost silently without much maintenance needed. That's why many data centers find this so appealing when dealing with limited space constraints, noise regulations, and wanting reliable performance day after day. Both methods beat traditional air cooling hands down when it comes to keeping things cool efficiently. But getting either system up and running takes serious infrastructure investment though. We're talking about installing pumps, heat exchangers, properly sealed loops throughout, plus hiring professionals who know what they're doing to prevent any water damage risks especially when multiple rigs are involved together.

Quantifying the Advantage: Water's Specific Heat Enables 3–5× Greater Heat Flux Handling

Liquid cooling has a real edge over traditional methods because water just handles heat so much better than air does. Water can absorb about 4.18 times more heat energy compared to air, and it conducts heat away at around 25 times the rate too. What this means in practice is that coolant systems based on water can move between three to five times more heat through each liter they circulate. The benefits are pretty clear when looking at actual hardware performance. When ASIC miners stay under 70 degrees Celsius, they maintain their best hashing speeds and see failure rates drop by roughly 40 percent compared to what happens with air cooling setups. From a financial standpoint, these efficiency gains matter a lot. For every ten degree drop in working temperature, power usage goes down about 4%. That makes investing in liquid cooled radiator systems not just smart but essential for big mining operations concerned with keeping equipment running longer, minimizing downtime, and ultimately maximizing profits over time.

Making the Right Choice: Matching Mining Radiator Technology to Operational Scale and Environment

FAQ

Q1: Why is thermal performance important in mining radiator selection?

A1: Thermal performance is crucial because it impacts the efficiency and reliability of mining rigs. High thermal performance ensures better heat dissipation, reducing the risk of overheating, hardware failure, and performance throttling, which are critical for maintaining profitable mining operations.

Q2: What are the key differences between air-cooled and liquid-cooled radiators?

A2: Air-cooled radiators, typically using aluminum fin designs, are cost-effective and straightforward but have limitations in high-density environments or rising ambient temperatures. Liquid-cooled radiators, such as cold-plate and immersion systems, offer superior efficiency by handling greater heat flux due to water's specific heat capacity but require significant infrastructure investment.

Q3: How does thermal resistance affect radiator reliability?

A3: Thermal resistance, measured in degrees Celsius per watt, indicates how well a radiator can transfer heat. Lower thermal resistance means better heat transfer, leading to cooler operating temperatures, prolonging component lifespan, and lowering failure rates, enhancing radiator reliability.

Table of Contents

- Why Thermal Performance Is the Core Criterion for Mining Radiator Selection

- Air-Cooled Mining Radiators: Cost-Effective Simplicity with Ambient-Dependent Limits

- Liquid-Cooled Mining Radiators: Higher Efficiency, Integration Complexity, and ROI Considerations

- Making the Right Choice: Matching Mining Radiator Technology to Operational Scale and Environment