Customized aluminum radiators for applications requiring reduced weight, corrosion resistance, and easy installation without compromising cooling efficiency.

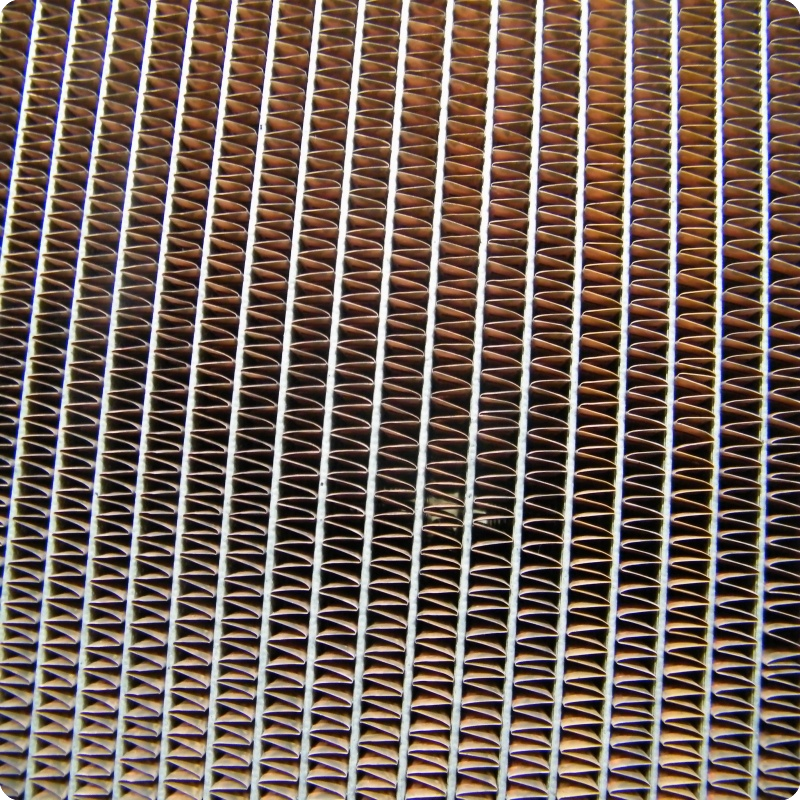

CT cores, or brazed copper fin-tube radiator cores, feature an integrated design where all tubes and fins are permanently bonded through brazing. This provides compact structure and good thermal conductivity, but once assembled, the tubes cannot be removed or serviced individually. Any internal clogging, corrosion, or leakage often requires replacing the entire core.

In contrast, the Removable Tube Copper Core by SINRUI Mining adopts a modular fin-tube design. Each tube can be independently removed for cleaning or replacement without disassembling the entire radiator. This structure maintains excellent heat transfer while enabling easier maintenance and lower long-term operating costs.

|

Performance & Maintenance Comparison

While both designs offer reliable cooling performance, their behavior in harsh mining environments differs significantly.

CT Core: Highly efficient at first, but its brazed, non-removable joints are prone to aging under high temperature and vibration, which can lead to coolant leakage and shortened service life.

Removable Tube Copper Core: Provides greater vibration resistance and easier maintenance access. The ability to replace single tubes prevents downtime from localized damage and extends overall radiator lifespan.

|

|

|

Case Study: Komatsu D85ESS Radiator Upgrade in South Africa

A SINRUI Mining customer in South Africa experienced repeated coolant leakage in their Komatsu D85ESS bulldozer equipped with a CT-type copper finned radiator. Due to the core’s integrated brazed structure, repair was difficult and required full replacement once a section failed.

|

| The upgraded system delivered better cooling performance and stronger vibration resistance. Overall, the radiator achieved longer service life and sustained thermal reliability in the demanding mining environment. |

|

|

The upgraded system delivered better cooling performance and stronger vibration resistance. Overall, the radiator achieved longer service life and sustained thermal reliability in the demanding mining environment.

|